Energy Efficiency Reimagined OTCQX: TGEN LPG Near Zero Emission System for Forklifts – Status Update Robert Panora President & COO

Topics Tecogen Inc. Technology Background Ultera® Aftertreatment Process Application to Forklifts Regulatory issues MCFA Work Emissions Performance (modified 2.5 L GCT LPG engine) Program Status Origin Engines Agreement Future Final Thoughts & Questions 2

Tecogen Inc. CHP OEM Installations & Service Technology development - emissions ✓ 125 kW ✓ Proprietary inverter ✓ CERTS certified microgrid system ✓ Blackout protection ✓ 60 -75 KW ✓ Cost effective heat and power 3 ✓ Gas cooling –lower operating costs ✓ 50 – 400 Tons ✓ “Free” waste heat

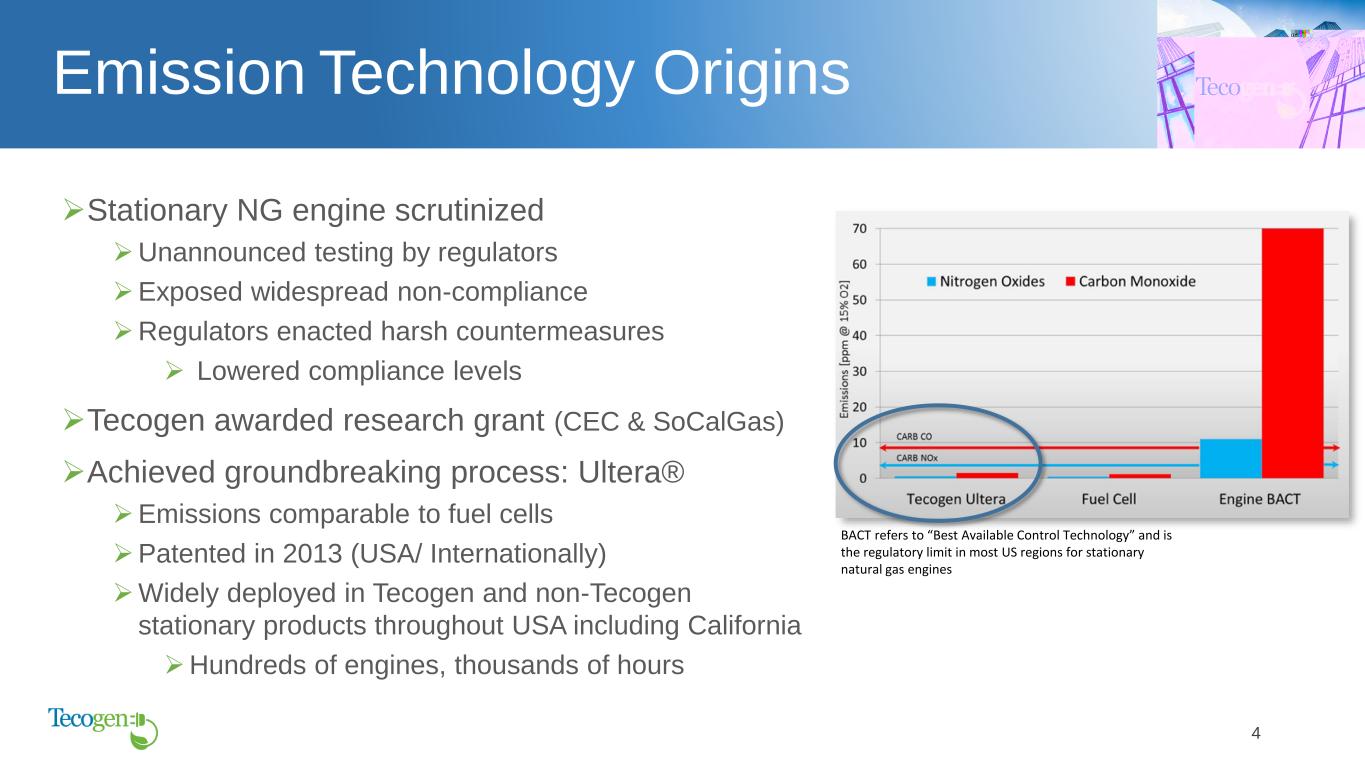

Emission Technology Origins ➢Stationary NG engine scrutinized ➢Unannounced testing by regulators ➢Exposed widespread non-compliance ➢Regulators enacted harsh countermeasures ➢ Lowered compliance levels ➢Tecogen awarded research grant (CEC & SoCalGas) ➢Achieved groundbreaking process: Ultera® ➢Emissions comparable to fuel cells ➢Patented in 2013 (USA/ Internationally) ➢Widely deployed in Tecogen and non-Tecogen stationary products throughout USA including California ➢Hundreds of engines, thousands of hours BACT refers to “Best Available Control Technology” and is the regulatory limit in most US regions for stationary natural gas engines 4

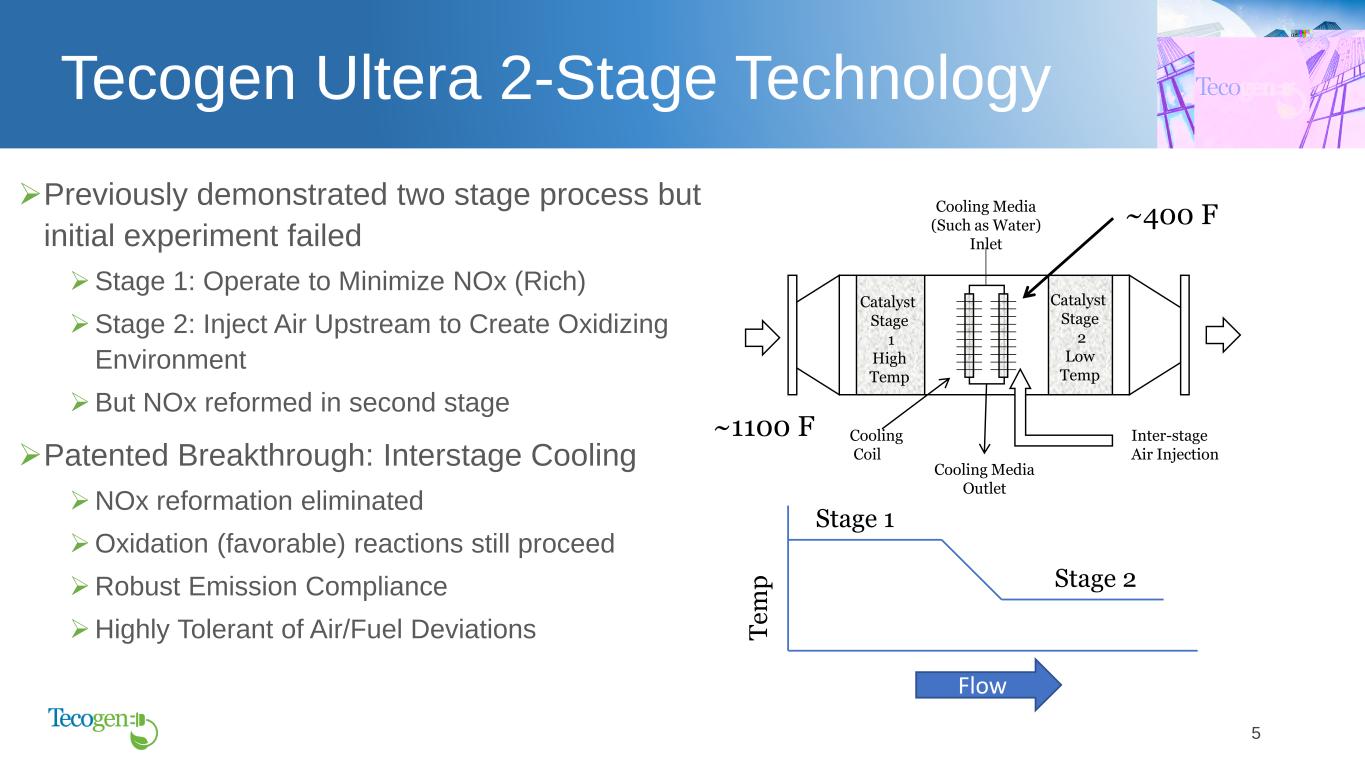

Tecogen Ultera 2-Stage Technology ➢Previously demonstrated two stage process but initial experiment failed ➢Stage 1: Operate to Minimize NOx (Rich) ➢Stage 2: Inject Air Upstream to Create Oxidizing Environment ➢But NOx reformed in second stage ➢Patented Breakthrough: Interstage Cooling ➢NOx reformation eliminated ➢Oxidation (favorable) reactions still proceed ➢Robust Emission Compliance ➢Highly Tolerant of Air/Fuel Deviations Catalyst Stage 1 High Temp Catalyst Stage 2 Low Temp Inter-stage Air Injection ~1100 F Cooling Coil Cooling Media (Such as Water) Inlet Cooling Media Outlet ~400 F T e m p Flow Stage 1 Stage 2 5

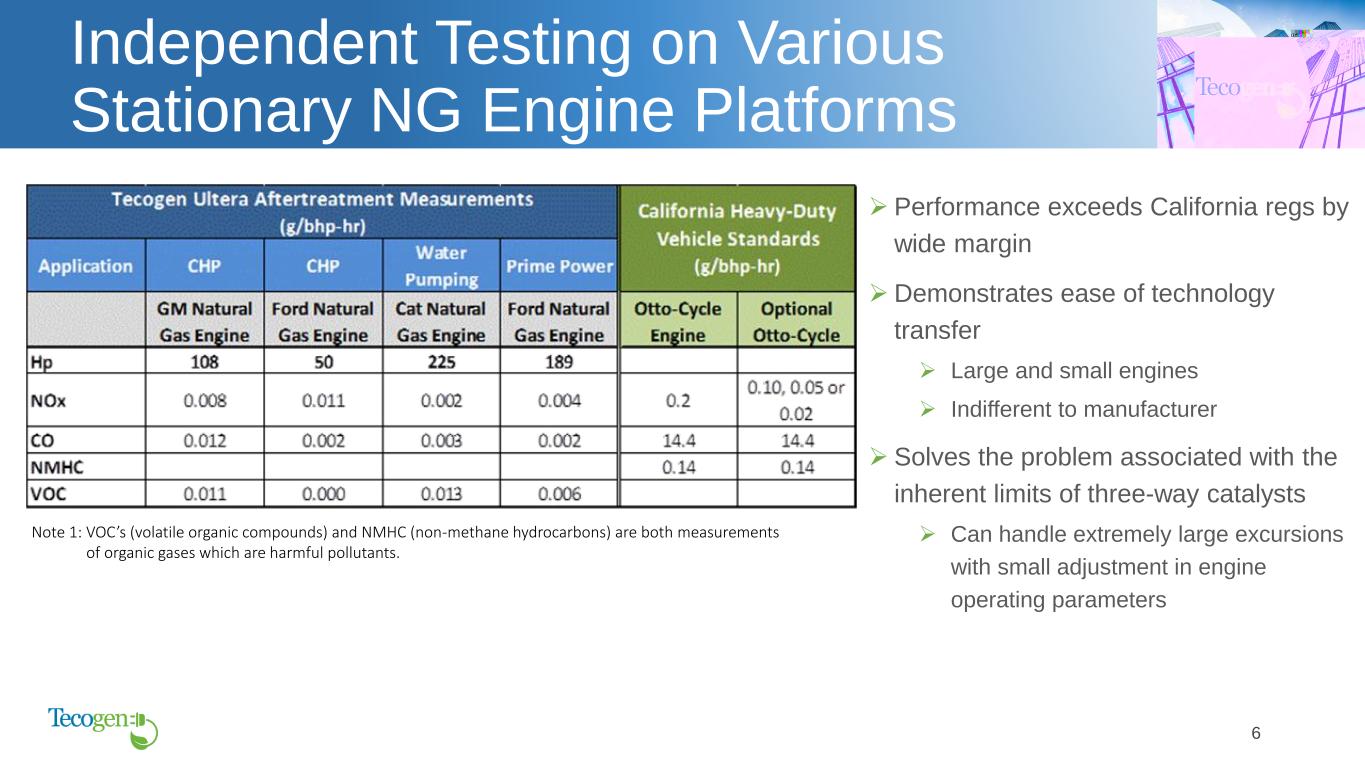

Independent Testing on Various Stationary NG Engine Platforms ➢ Performance exceeds California regs by wide margin ➢Demonstrates ease of technology transfer ➢ Large and small engines ➢ Indifferent to manufacturer ➢ Solves the problem associated with the inherent limits of three-way catalysts ➢ Can handle extremely large excursions with small adjustment in engine operating parameters Note 1: VOC’s (volatile organic compounds) and NMHC (non-methane hydrocarbons) are both measurements of organic gases which are harmful pollutants. 6

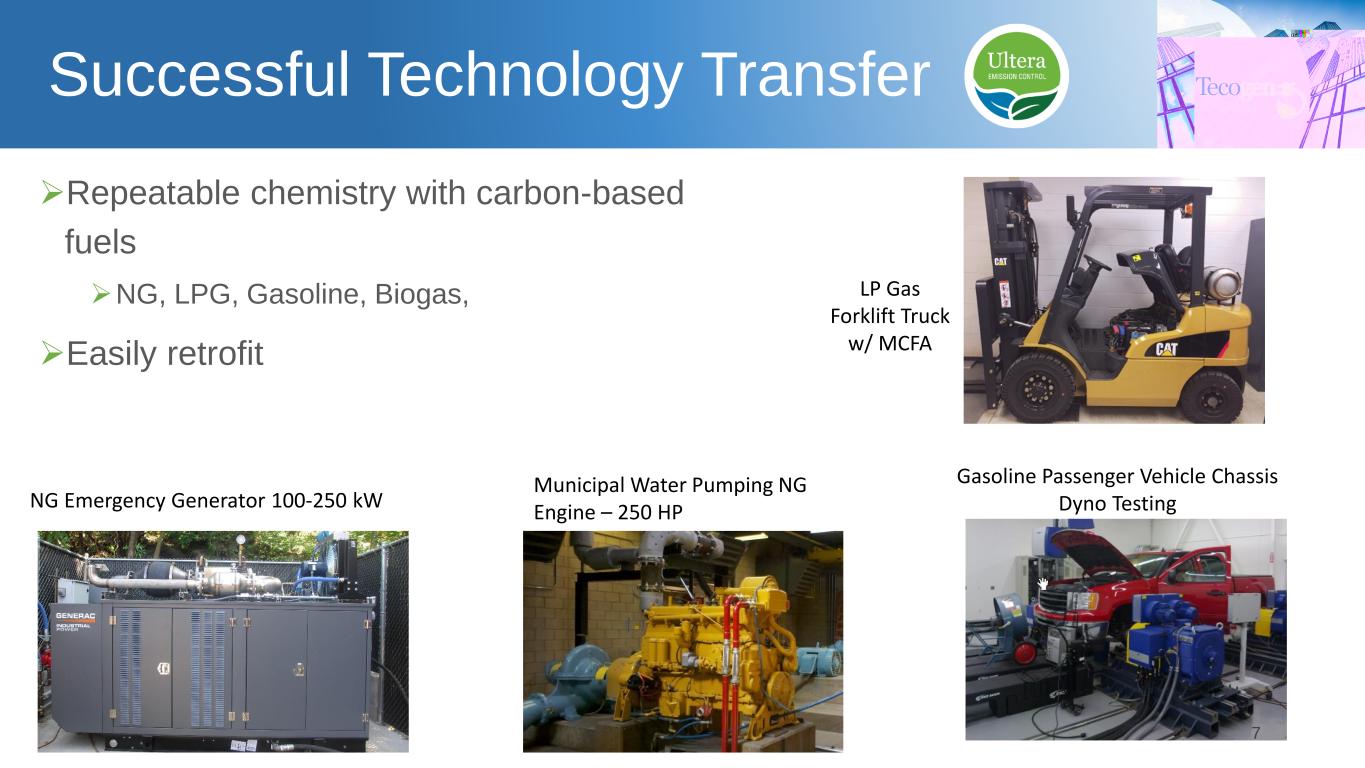

Successful Technology Transfer ➢Repeatable chemistry with carbon-based fuels ➢NG, LPG, Gasoline, Biogas, ➢Easily retrofit NG Emergency Generator 100-250 kW Municipal Water Pumping NG Engine – 250 HP Gasoline Passenger Vehicle Chassis Dyno Testing 7 LP Gas Forklift Truck w/ MCFA

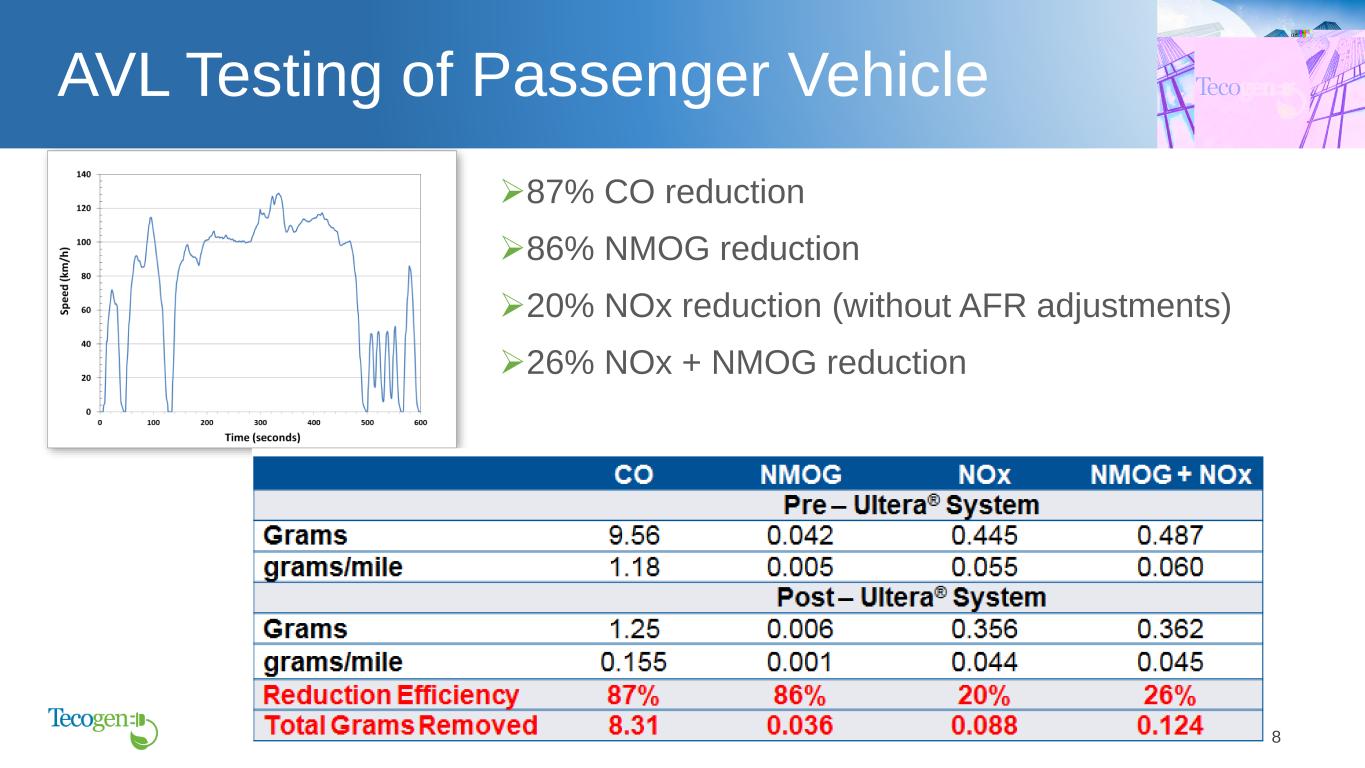

AVL Testing of Passenger Vehicle ➢87% CO reduction ➢86% NMOG reduction ➢20% NOx reduction (without AFR adjustments) ➢26% NOx + NMOG reduction 8

Forklift Initiative Ultera process fits well with forklift application Engine duty cycle exceptionally variable Ultera emissions performance tolerant of air/fuel ratio excursions CO elimination highly valued because of indoor air quality consideration Many low emissions technologies singularly focus on NOx (high concentrations of CO and HC’s) Demonstration Program initiated Objective Demonstrate low emissions on LPG on Ultera-equipped forklift Other participants: Propane Research and Education Council (PERC) funding MCFA (Mitsubishi Caterpillar Forklift America Inc.) vehicle donation and tech support 9

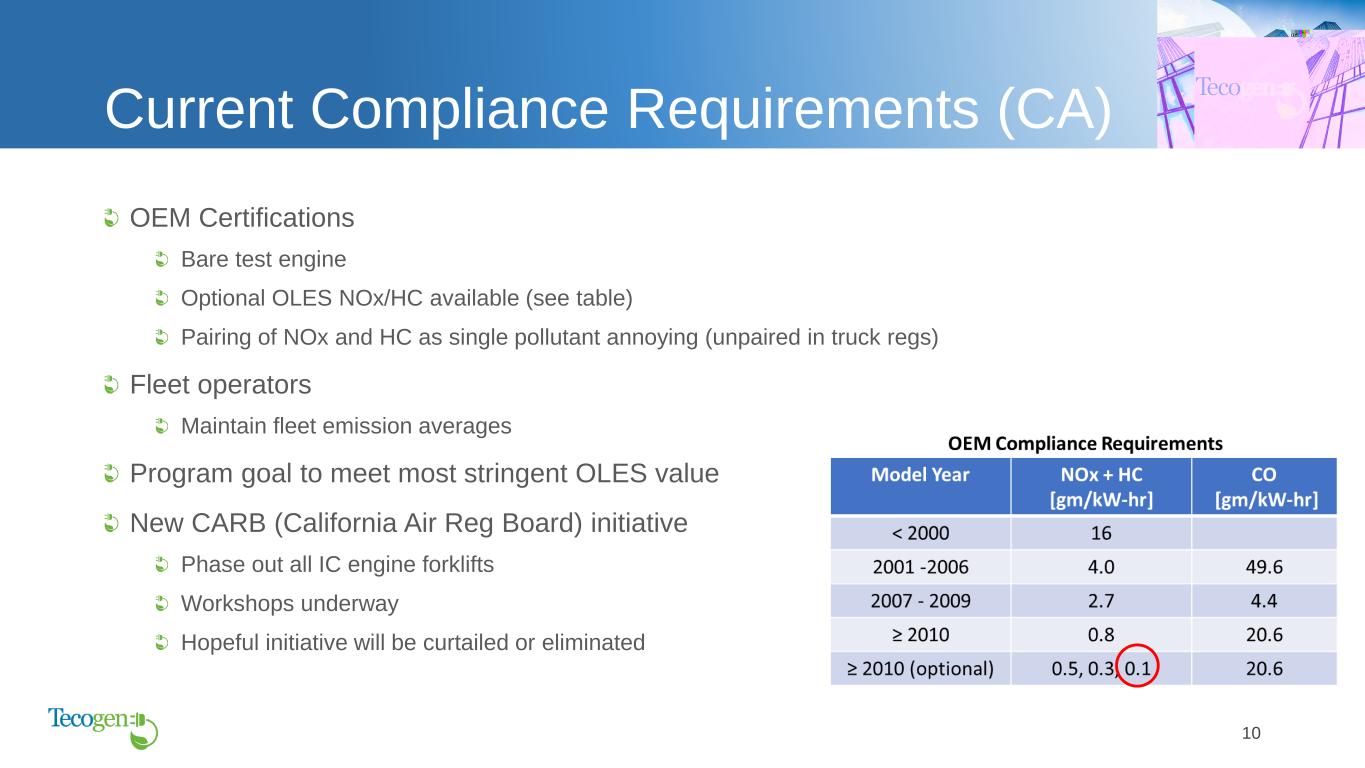

Current Compliance Requirements (CA) OEM Certifications Bare test engine Optional OLES NOx/HC available (see table) Pairing of NOx and HC as single pollutant annoying (unpaired in truck regs) Fleet operators Maintain fleet emission averages Program goal to meet most stringent OLES value New CARB (California Air Reg Board) initiative Phase out all IC engine forklifts Workshops underway Hopeful initiative will be curtailed or eliminated 10

Ultera Forklift Integration 11 Stock MCFA lift truck features Model GP25N (2.5L engine) 5000 lb capacity GCT (Global Component Technology) fuel system Three-way catalyst Muffler Radiator

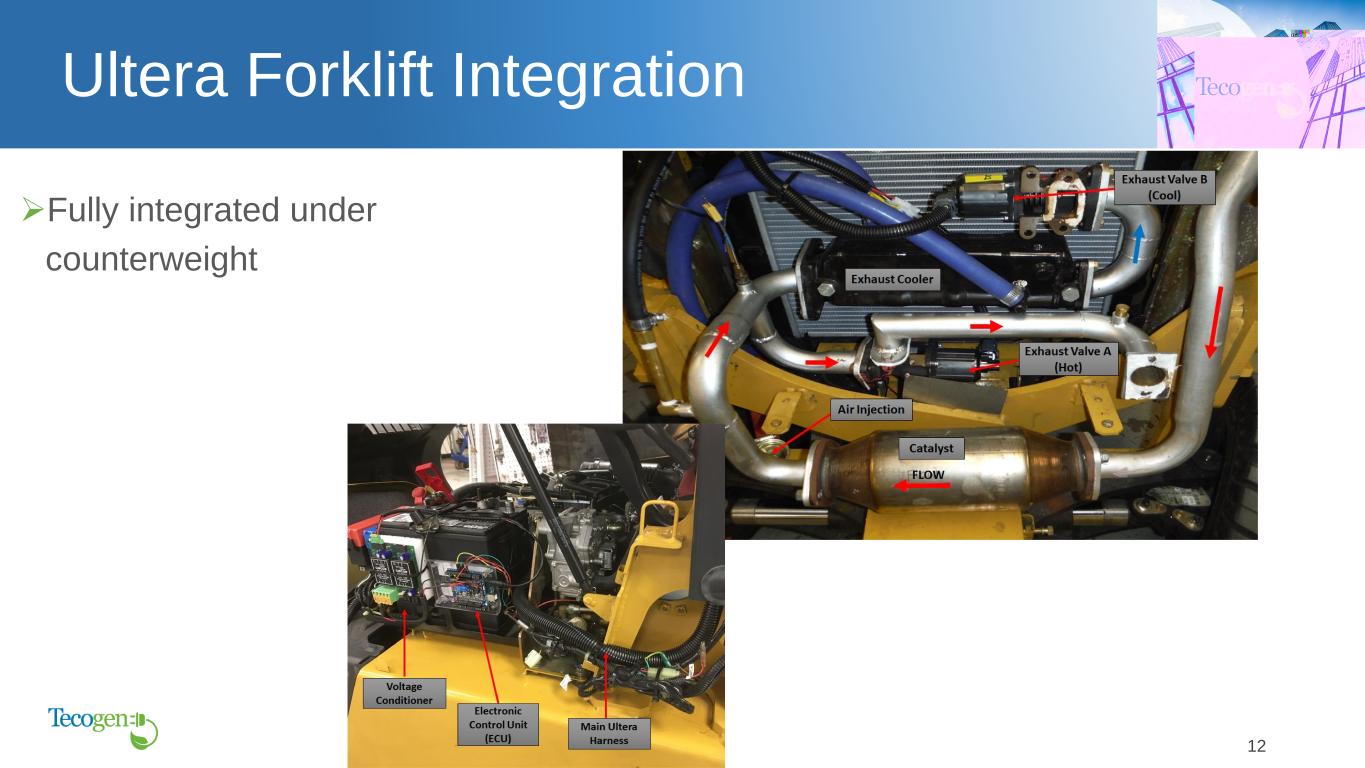

Ultera Forklift Integration ➢Fully integrated under counterweight 12

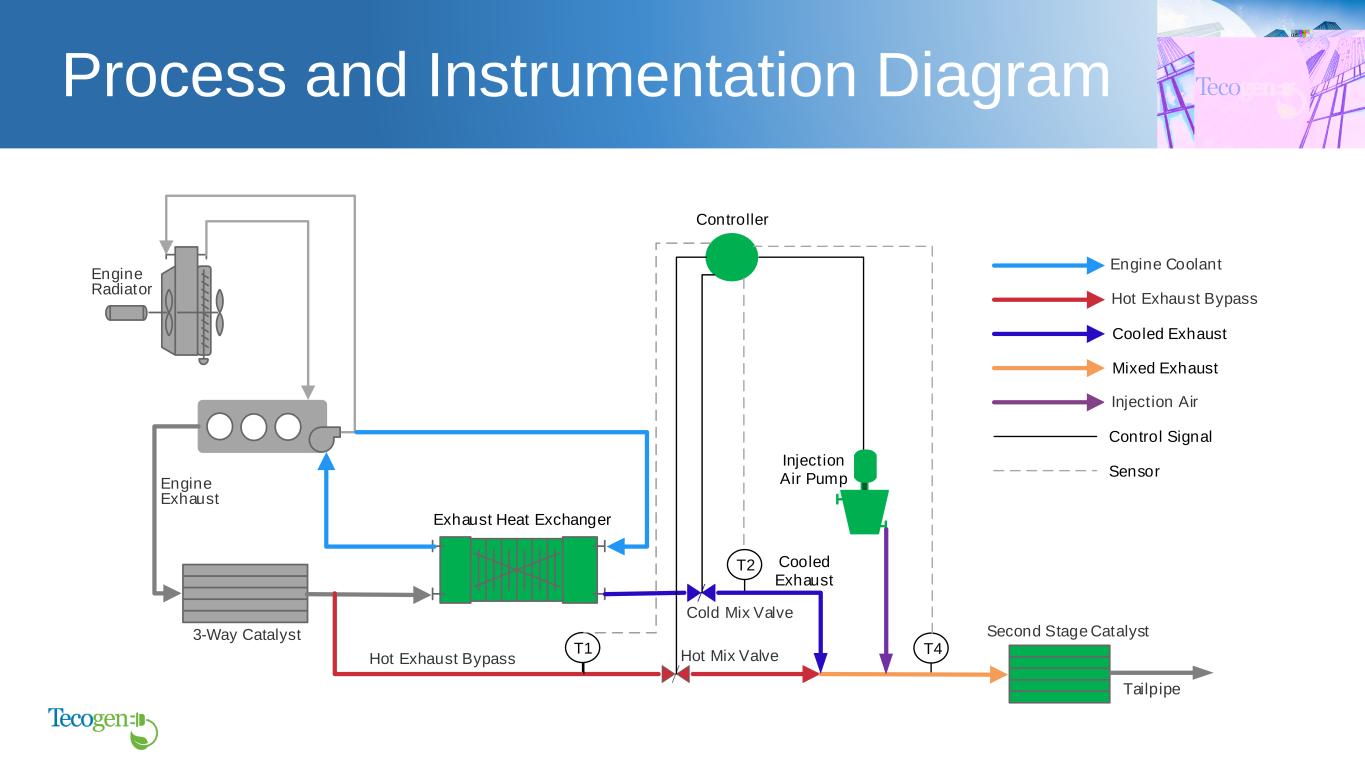

Process and Instrumentation Diagram 3-Way Catalyst Engine Exhaust Engine Radiator Exhaust Heat Exchanger Second Stage Catalyst Hot Exhaust Bypass Hot Mix Valve Cooled Exhaust Cold Mix Valve Controller T4T1 T2 Injection Air Pump Tailpipe Engine Coolant Hot Exhaust Bypass Injection Air Cooled Exhaust Mixed Exhaust Control Signal Sensor

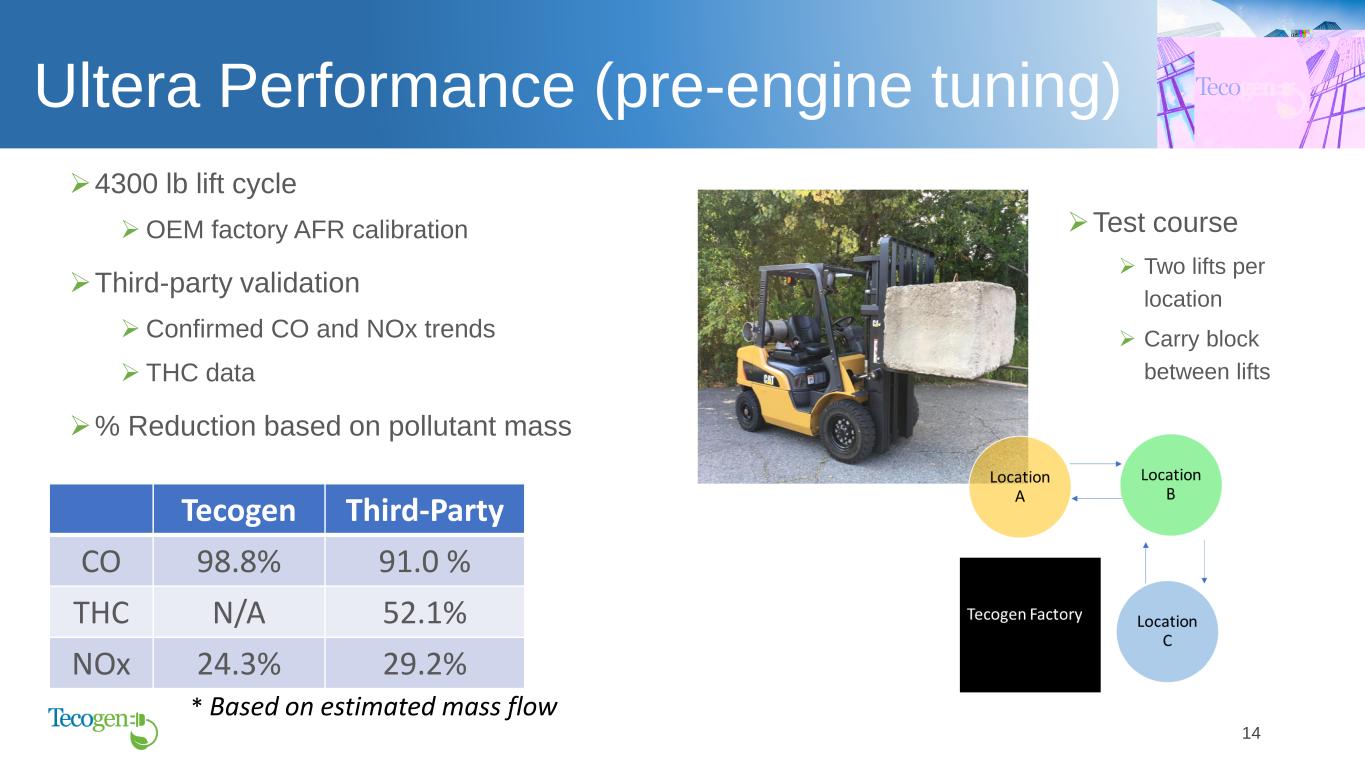

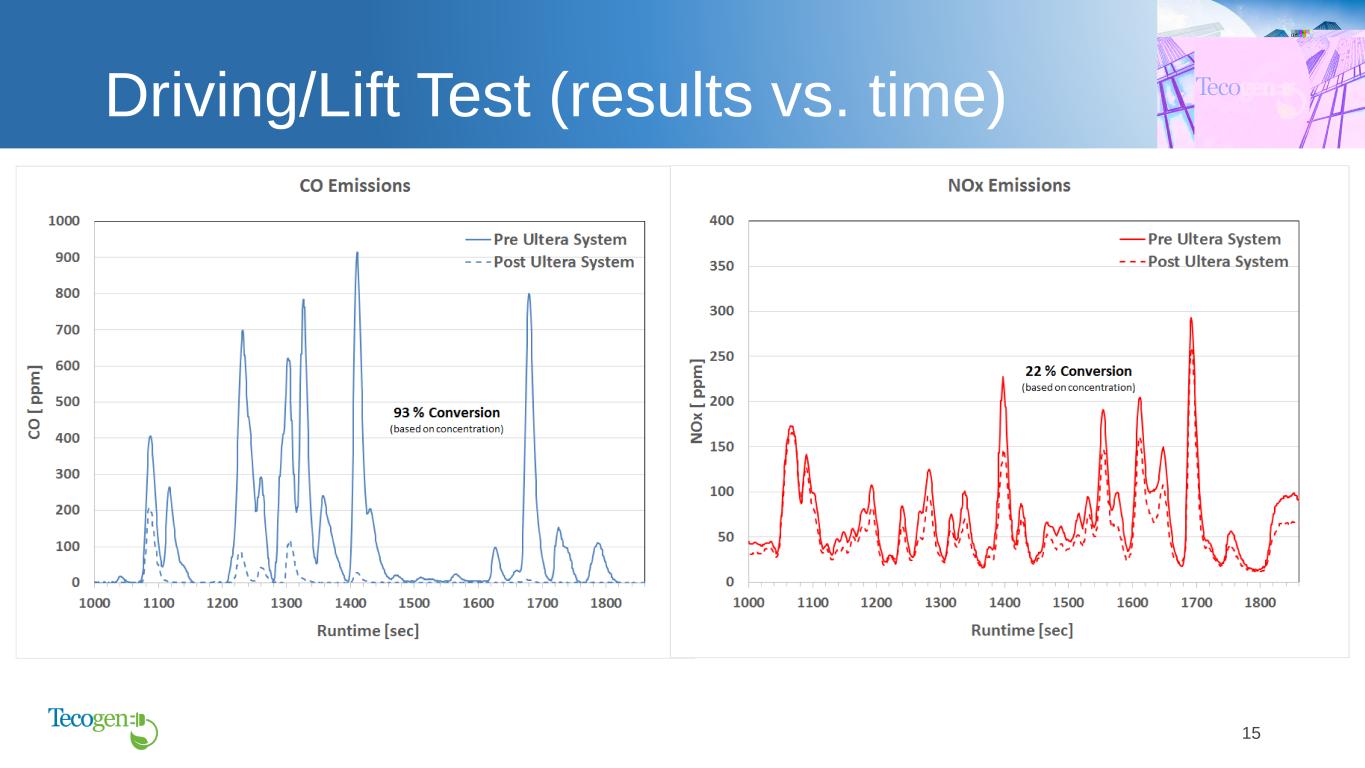

Ultera Performance (pre-engine tuning) ➢4300 lb lift cycle ➢OEM factory AFR calibration ➢Third-party validation ➢Confirmed CO and NOx trends ➢ THC data ➢% Reduction based on pollutant mass * Based on estimated mass flow Tecogen Third-Party CO 98.8% 91.0 % THC N/A 52.1% NOx 24.3% 29.2% 14 ➢Test course ➢ Two lifts per location ➢ Carry block between lifts

Driving/Lift Test (results vs. time) 15

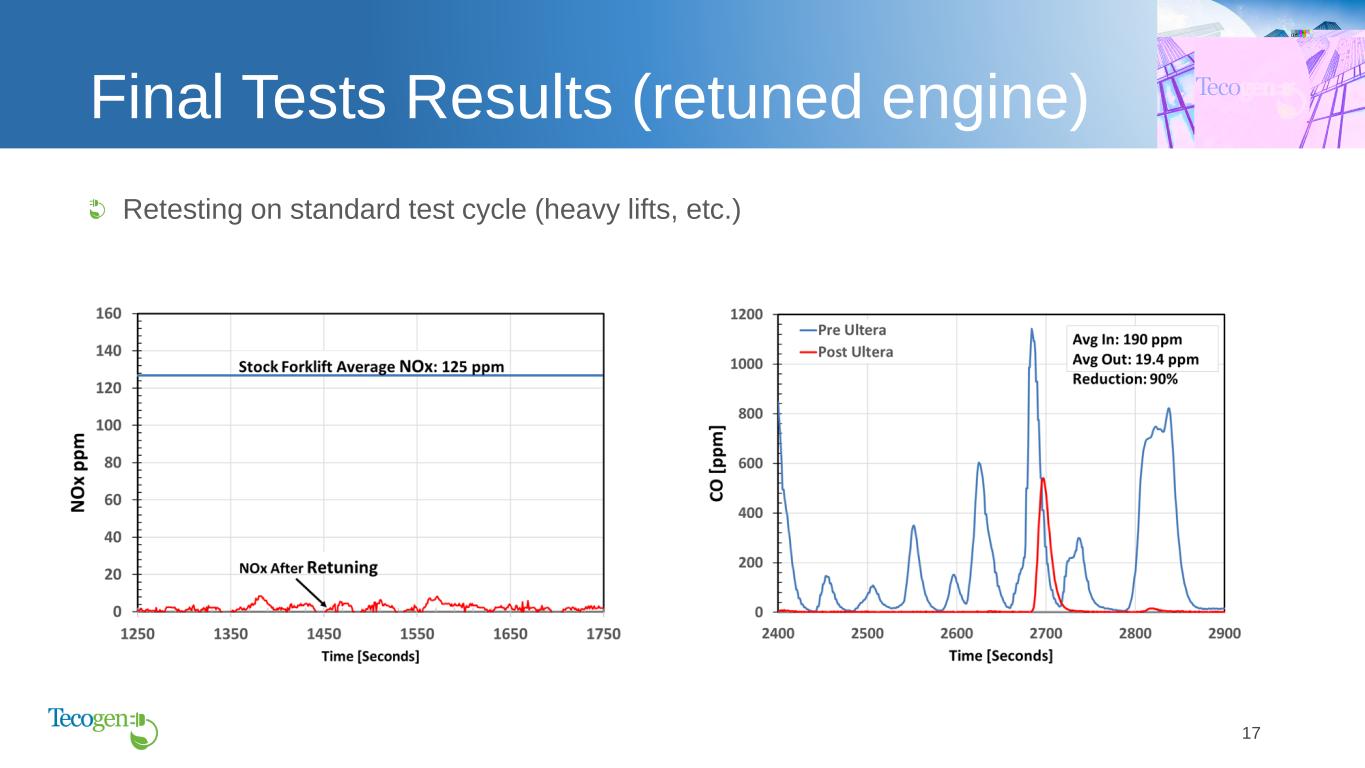

Engine Retuning (last step) Optimal Ultera performance required engine retuning Firmware changes in air-fuel ratio needed by programming specialist (Mitsubishi affiliate from Japan) Retuning objective is to bias air/fuel proportion for improved NOx reduction in first stage Retuning specialist from Japan and MCFA engineers performed retuning in 2019 Test results highly impactful CO and NOx levels highly reduced from stock forklift 16

Final Tests Results (retuned engine) Retesting on standard test cycle (heavy lifts, etc.) 17

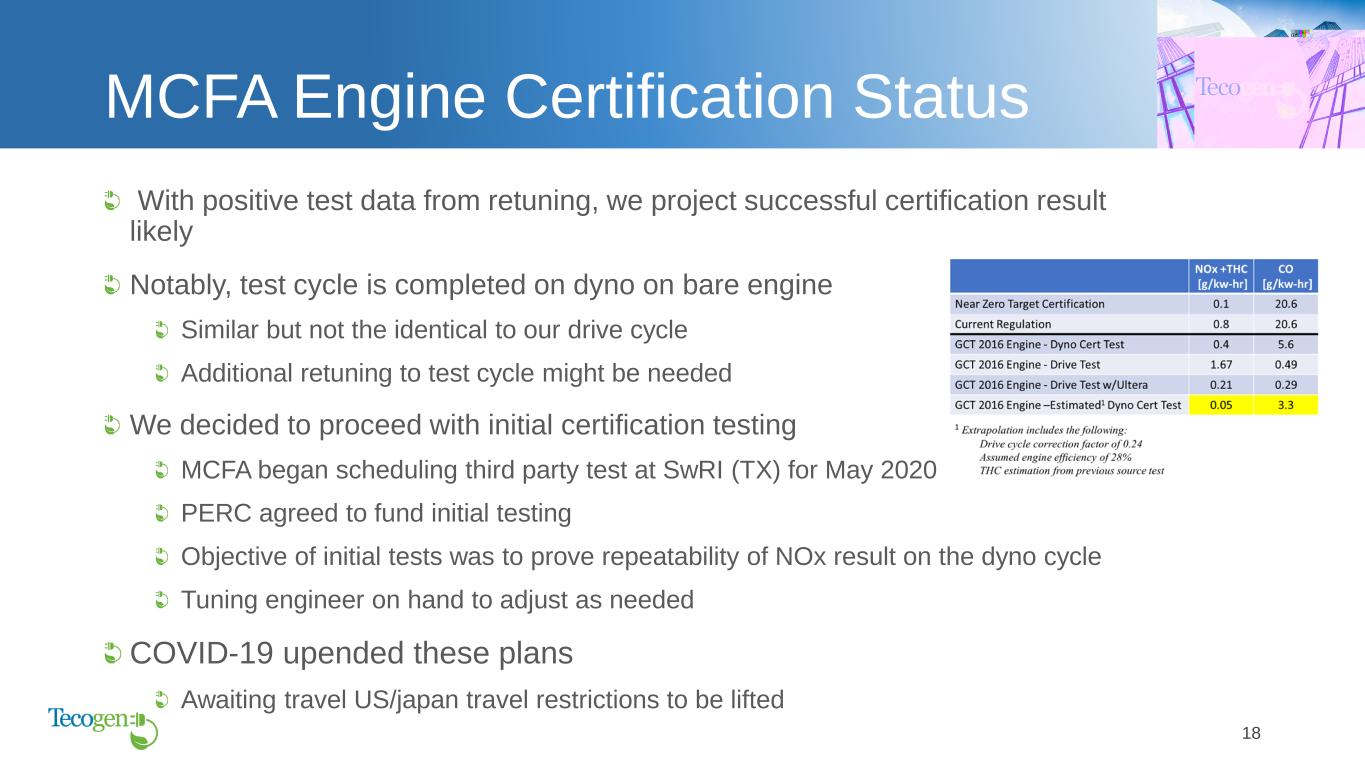

MCFA Engine Certification Status With positive test data from retuning, we project successful certification result likely Notably, test cycle is completed on dyno on bare engine Similar but not the identical to our drive cycle Additional retuning to test cycle might be needed We decided to proceed with initial certification testing MCFA began scheduling third party test at SwRI (TX) for May 2020 PERC agreed to fund initial testing Objective of initial tests was to prove repeatability of NOx result on the dyno cycle Tuning engineer on hand to adjust as needed COVID-19 upended these plans Awaiting travel US/japan travel restrictions to be lifted 18

Origin Engine Ultera Agreement Origin Engines Nebraska-based manufacturer Innovative, fast growing supplier in industrial markets Aware of growing value of low emissions to customers Tecogen supplier for our CHP products Tecogen/Origin License Agreement (November 2020) Engines 80 to 280 bhp (no conflict with MCFA) Propane, Natural gas, others Multiple markets covered Oil and gas, power generation, lift trucks, forestry, and distributed energy systems. 19 See also Feb 2021 article in Diesel Progress https://lnkd.in/efzs_B9

Future MCFA program COVID delay unfortunate MCFA remains enthusiastic about technology Origin agreement very positive outlook Strong potential to expand Ultera Other lift manufacturers and other markets Aggressive schedule for implementation Ongoing catalyst research Third party contracted by Tecogen to investigate improved Stage 2 formulations Opportunity for innovation because of low temp environment Laboratory Testing has identified more active, less expensive formulation Important to pursue 20

Final Thoughts and Questions Possible marketing strategies Program originally emphasized certification to CA OLES (or near zero) Certification has value but limited to outdoor air-quality concerns Alternative would be to emphasize indoor air-quality impact Universal appeal (not limited to California) Potential to attain low values for all pollutants which is unusual. Further reading (SAE International papers) NOx Reduction Using a Dual-Stage Catalyst System with Intercooling in Vehicle Gasoline Engines under Real Driving Conditions https://www.sae.org/publications/technical-papers/content/2018-01-0335/ Development and Testing of the Ultera ® Dual Stage Catalyst System on Gasoline-Fueled Light Duty Vehicles https://www.sae.org/publications/technical-papers/content/2017-01-0920/ 21 Thank You!